Multiple Maximum Quantity Scenarios

Characteristic

Short description

Maximum quantity scenarios are used to model the maximum load in several dimensions that can be transported by a vehicle![]() The term vehicle describes what is being routed or planned for. Vehicles are used in route calculation, distance matrix calculation and effectively also in tour planning. In route calculation, vehicle properties like overall size, weight and speed are in focus. In tour planning, it is vehicle properties like capacity and availability.

Commonly a vehicle is motorized, like a truck - including its trailer or a car. However also a bike or even a pedestrian are included in this definition..

Using multiple maximum quantity scenarios the user can specify various configurations of a vehicle.

The term vehicle describes what is being routed or planned for. Vehicles are used in route calculation, distance matrix calculation and effectively also in tour planning. In route calculation, vehicle properties like overall size, weight and speed are in focus. In tour planning, it is vehicle properties like capacity and availability.

Commonly a vehicle is motorized, like a truck - including its trailer or a car. However also a bike or even a pedestrian are included in this definition..

Using multiple maximum quantity scenarios the user can specify various configurations of a vehicle.

Use

By providing a maximum quantity scenario the user can specify how much of certain goods can be transported by a vehicle. Depending on the vehicle configuration or varying sizes of goods the user may want to specify multiple maximum quantity scenarios, each representing a combination of various load types on the vehicle. Furthermore, the user can specify whether the applied maximum quantity scenario can be switched at every stop or only between trips.

Examples for use cases:

- Pallets and boxes:

Suppose a vehicle can transport pallets and boxes. A maximum quantity scenario describes a combination of a number of pallets and a number of boxes that can be loaded onto the vehicle at the same time, e.g. 10 boxes and 1 pallet or 2 boxes and 2 pallets. Pallets are modeled as one dimension of a maximum quantity scenario, boxes as another dimension. Several combinations may be possible and one can switch between them whenever necessary.

- Multiple compartments with mobile partition wall:

Consider a vehicle that has multiple compartments to transport groceries, e.g. one for frozen and one for fresh vegetables. Between the compartments is a partition wall that can be moved such that either more frozen or more fresh vegetables can be transported. Multiple maximum quantity scenarios can be used to model every configuration of that partition wall. However, moving the partition wall requires some tools only available at a depot, so switching between the scenarios can only be done between trips.

Detailed Consideration

Maximum quantity scenarios are specified at every vehicle. Each maximum quantity scenario specifies the maximum quantity of every kind of load which occurs in a transport order. At every position within a valid tour, at least one maximum quantity scenario must be valid. Furthermore, the user can specify whether the maximum quantity scenario can change at any stop or only between trips. Depending on the load on a vehicle, multiple quantity scenarios may be valid at the same time. The algorithm chooses the applied maximum quantity scenarios, such that the number of changes between scenarios are minimized. After that, the scenarios are chosen in order of their appearance. If no valid maximum quantity scenarios can be found for an input tour, the violations are reported with respect to the very first maximum quantity scenario for the whole tour. This means, that even if there is a valid maximum quantity scenario for parts of the tour, violations for these parts are also considered with respect to the very first quantity scenario.

Example

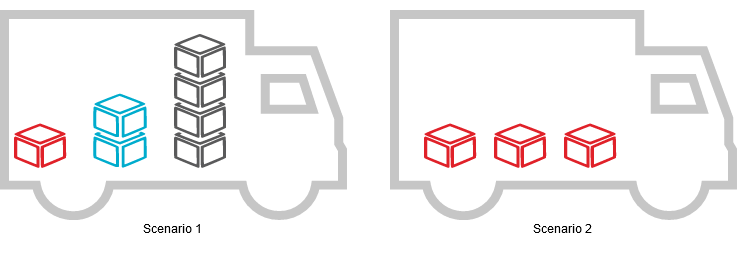

Consider a vehicle with two maximum quantity scenarios:

- Scenario 1: 4 units of load type A fit onto the vehicle with 2 units of load type B and 1 unit of load type C.

- Scenario 2: 3 units of load type C only fit onto the vehicle with 0 units of load type A and B

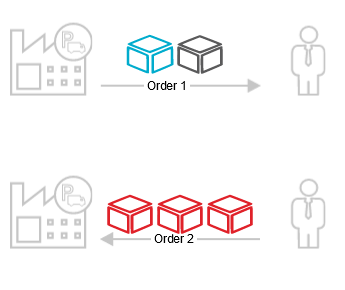

Now consider two orders in a request:

- A delivery from a depot to a customer with load of one unit of load type A and B each.

- A pickup from that same customer with three units load of type C.

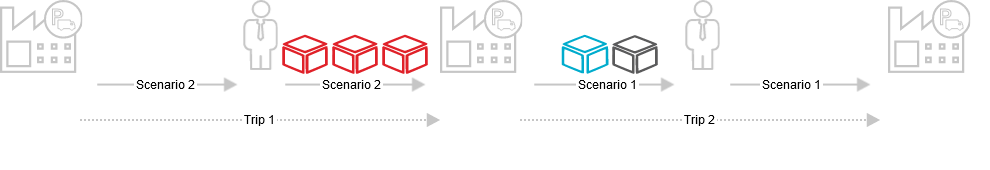

Assume that switching the maximum quantity scenario is only allowed between trips. Then these two orders can only be transported in separate trips.

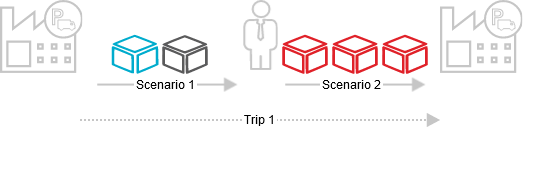

If switching the maximum quantity scenario at any stop is allowed, the two orders can be served in one trip. The valid quantity scenario switches at the customer from scenario 1 to scenario 2.

Good to know

Allowing to switch maximum quantity scenarios only between trips requires more computation time than allowing it at every stop. Furthermore, the computational effort increases with the number of scenarios as well as with their size. To avoid unnecessary performance loss, only use pareto-optimal scenarios, i.e. do not use scenarios that fit into others.

Related Topics

| Technical Concept | Orders, Locations, and Stops |

| Technical Concept | Tours and Trips |